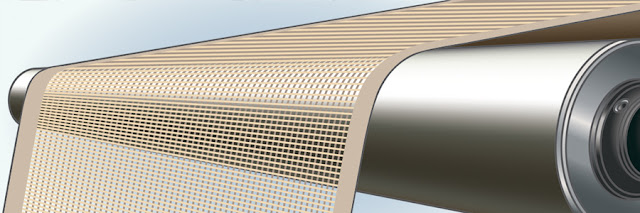

Know why we use PTFE for making Conveyor Belts

PTFE is – Polytetrafluoroethylene is a highly durable and non-flammable resin that is made with the process of polymerization of Tetrafluoroethylene. We use this material for several purposes and one of them is to manufacture the conveyor belts that are used in the machines installed mainly in food industries. The reason is that it has several qualities like: It is flame resistant which means it has excellent tolerance for high temperatures, auto-ignition, and melting point. So, if your PTFE conveyor belts are used in high-temperature conditions, they can easily tolerate it and work great. You don’t have to worry about changing the belts again and again because these are made with the toughest material which means once invested in the same, you can reap benefits for long. Even if the belts come in direct contact with the extremely hot surface, there is no issue. It will work effectively. The PTFE material is highly resistant to weather fluctuations. These can easily ...